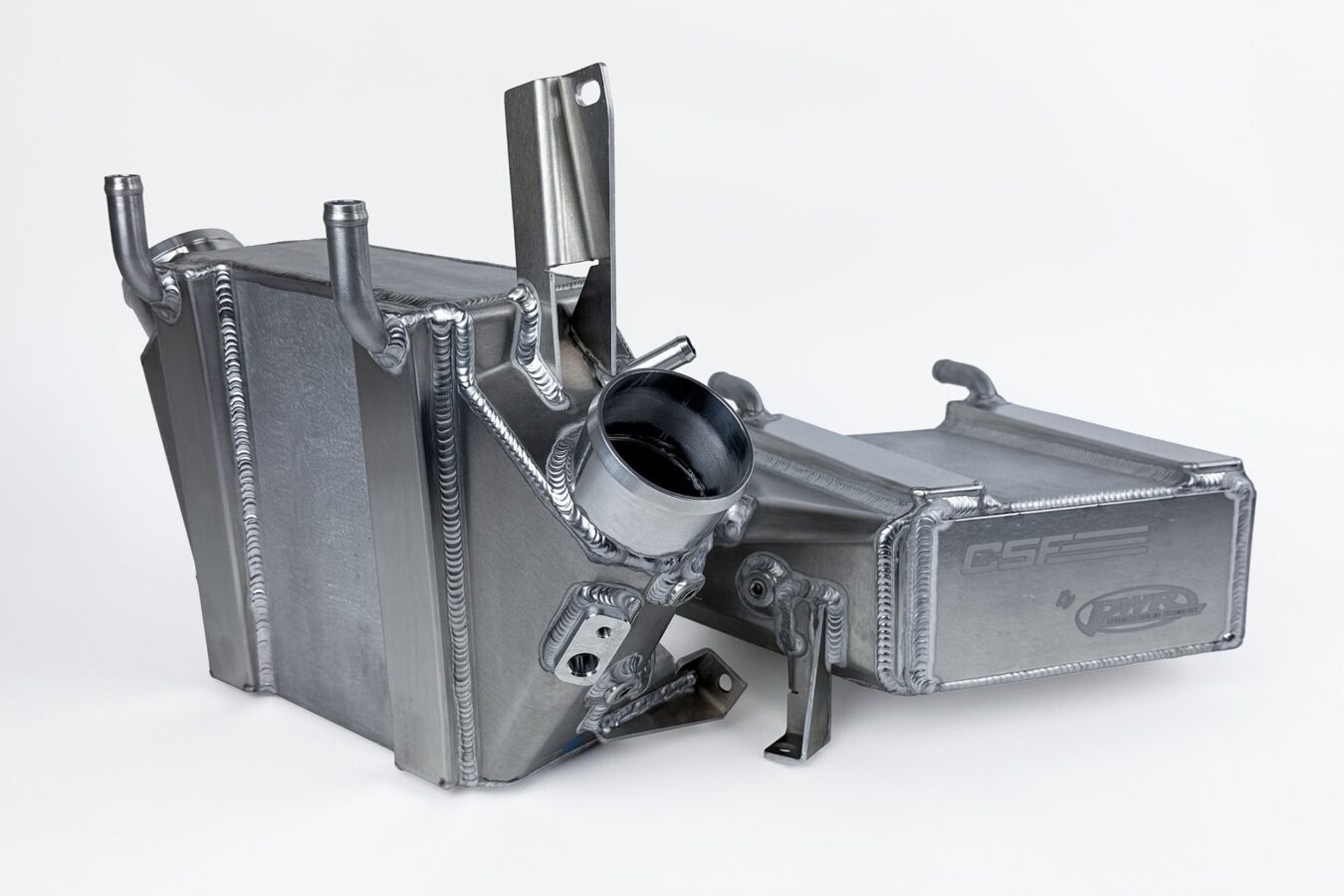

CSF McLaren 720S / 765LT / 750S / GT / GTS Charge-Air-Coolers

- Sold as a pair (Left & Right Charge-Air-Coolers / Intercoolers)

- Faster recovery of Intake Air Temperatures (IATs)

- No pressure drop compared to the OEM core

- High-performance bar/plate intercooler core by PWR pressure tested to 120psi

- Plug-and-Play “Drop-in Fit” Installation – Requires No Modifications

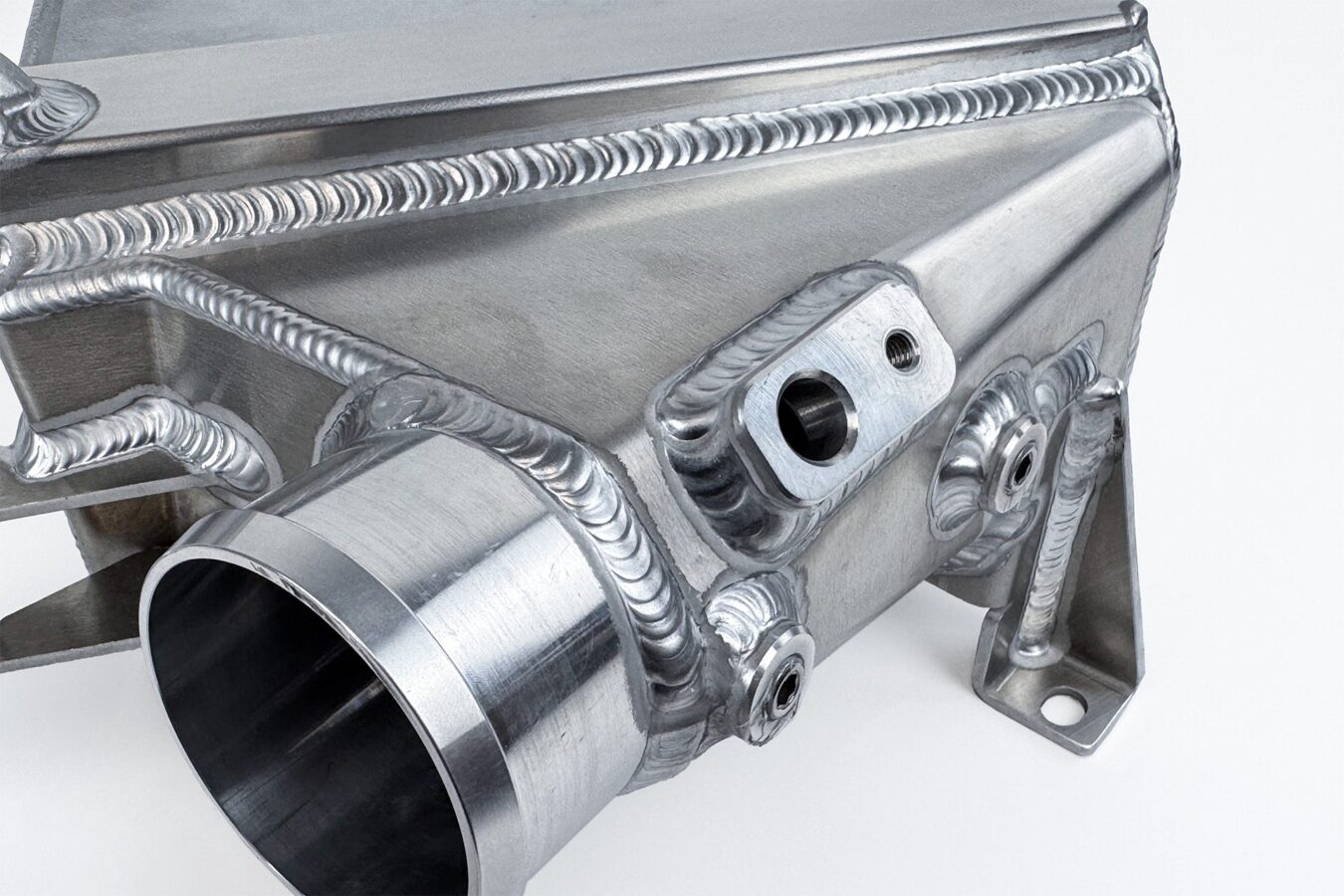

- CNC Machined Mounting Brackets and OEM Style Inlet/Outlet

- 100% All Aluminum TIG-Welded Construction

- Hand Brushed Satin Finish

- True Plug-and-Play “Drop-in Fit” Installation Requires Absolutely No Modifications

- Individually Leak and Pressure Tested

- Limited Lifetime Warranty

CSF’s original Charge-Air-Coolers (Intercoolers) for the McLaren 720S made waves when released in 2021. This system achieved an astonishing 99% thermal efficiency and could be found in the fastest and most powerful McLarens in the world. However, even proven success can be improved. In 2024, CSF returned to the drawing board to address fitment for Spider models and streamline manufacturing amid ongoing supply chain challenges.

The result is an all-new, reengineered Charge-Air-Cooler system developed in partnership with CSF’s strategic partner, PWR. Compact, more efficient, and now compatible with Spider models, this next-generation system sets a new benchmark in performance cooling for the McLaren 720S, 765LT, GT, as well as the new 750S and GTS.

This updated system was developed in collaboration with PWR, one of CSF’s strategic manufacturing partners. PWR is recognized for its motorsports expertise, manufacturing cooling systems for F1, WRC, MotoGP, and other high-performance racing series. Together, CSF & PWR have created a high-performance solution tailored for the most demanding McLaren owners, tuners, and race teams.

Both CSF and PWR are Tier-1 OEM-certified cooling manufacturers that specialize in high-performance heat exchangers. These new McLaren Charge-Air-Coolers use advanced core technology, optimized for minimal pressure drop and maximum thermal transfer. Each pair of coolers is made in the USA, with in-house pressure testing and quality inspections, to meet the stringent demands of McLaren owners. This system delivers unmatched cooling performance for the 4.0L twin-turbo V8 (M840T) found in the 720S, 765LT, 750S, GT, and GTS. The CSF by PWR Charge-Air-Coolers are handcrafted and professionally TIG-welded in the USA. Each unit is crafted with the highest level of craftsmanship and durability unmatched anywhere else in the aftermarket.

The OEM McLaren units are very well-engineered, offering up to 94% thermal efficiency while handling modest boost increases quite effectively. This strong baseline performance made developing an upgraded system quite challenging. CSF’s original design (#8186) managed 99% efficiency, but the larger cores caused fitment issues for the Spider models. The new design solves this, delivering exceptional performance in a more compact package that fits all GT, GTS, 720S, 765LT, and 750S variants.

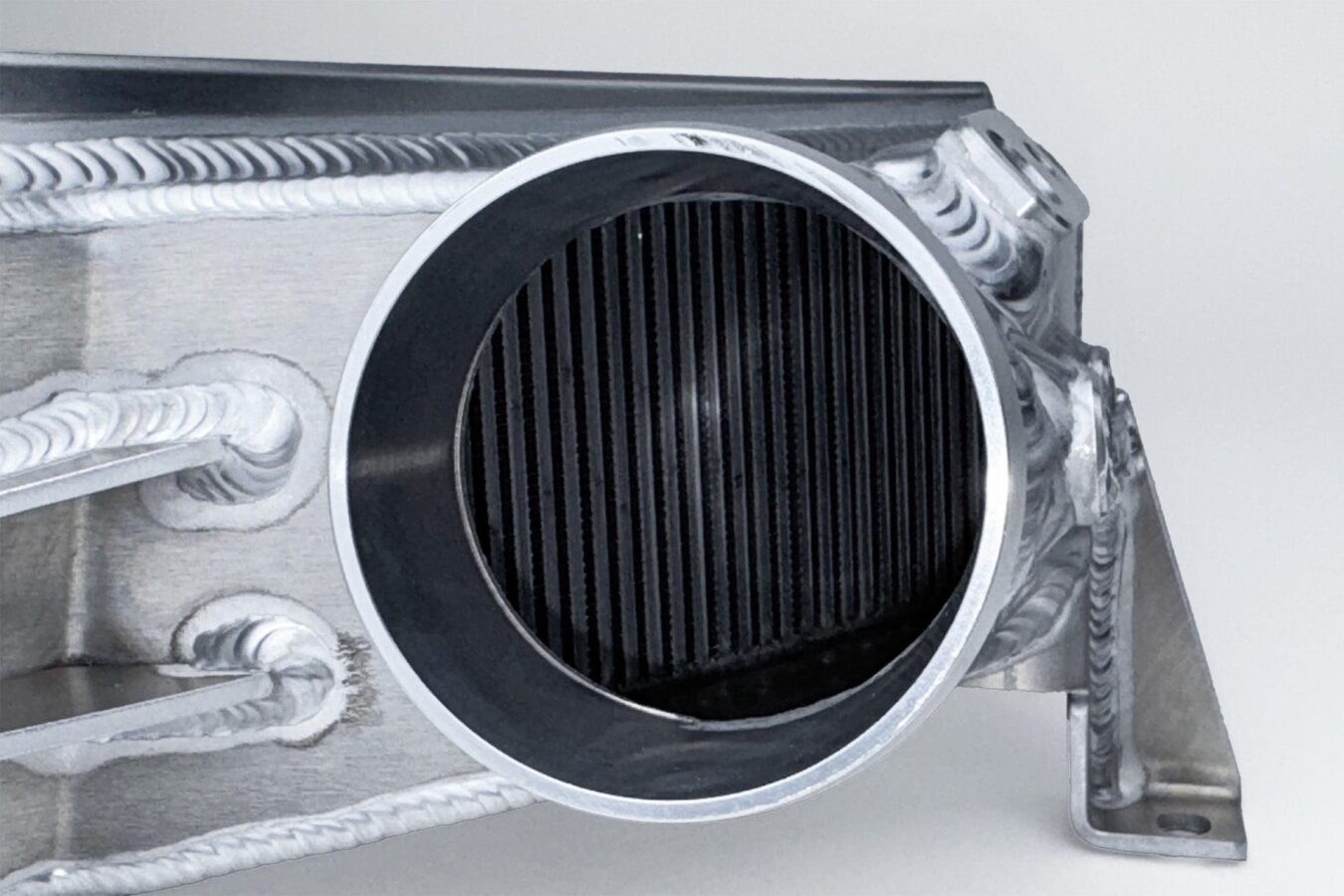

Formula 1 Grade Core: The new CSF coolers feature hand-built bar/plate cores manufactured in PWR’s Tier-1 OEM facility here in the USA (Indianapolis, IN). Each core is produced to aerospace-level tolerances using extremely lightweight and thin materials. This allows for a higher concentration of internal fins, maximizing heat transfer efficiency. The PWR bar/plate core uses 3 times as many fin rows compared to the factory tube & fin core. Bar/plate cores also have a much higher burst pressure rating and can take the stress of boost spikes much better than tube/fin cores.

What makes these cores exceptional isn’t just the materials, but also the craftsmanship. Building each core is an intensive process that requires expert technicians and precision welders capable of working with cladding as thin as 0.3 mm. Only five cores can be built per day by a qualified technician, and welding them requires the highest level of fabrication skill.

Tank Design & Construction: One of the other shortcomings of the factory coolers is their ability to handle high boost. The factory coolers are an all-metal construction with extrusion-formed tanks brazed to the cores. This is much stronger than the more common plastic tank with crimped-on gasket seals, but it still leaves room for improvement. The brazed joint remains a weak spot in the system and can rupture at higher boost pressures. The new CSF Charge-Air-Coolers are fully TIG welded to the aluminum tanks. This construction method offers the strongest possible coolers, which can handle much higher boost pressures than the factory coolers.

FREQUENTLY ASKED QUESTIONS

If it's in stock and ready to roll, your order usually hits the road within 1–3 business days.

For made-to-order or specialty items (like carbon fiber parts or custom builds), the turnaround can take up to 8 weeks — perfection takes time.

Either way, we'll keep you updated so you know exactly when your parts are leaving the pit lane.

Absolutely! Once your order ships, you'll receive an email with a tracking link so you can follow its journey from our shop to your doorstep.

If your order ships via freight, you'll get a separate email with a direct link to the carrier's tracking page — easy and stress-free.

Things happen on the road — even to boxes. If your order arrives damaged, snap a few clear photos of the box and product and send them our way right away.

If your shipment is lost, just email or call us — we'll help track it down and guide you through the next steps to make it right.

Simple — spread the horsepower! Follow us on Instagram, YouTube, and Facebook, and most importantly, drop us a review on Google or Yelp to let others know about your experience.

Your feedback helps us grow, create more content, and keep bringing performance-driven parts to the community. 🏁

1ST CLASS SERVICE

805-267-9762or email Support@FFPerformance.co

Car parts can be a maze — good thing we brought the map. Our team's here to keep things smooth, simple, and maybe even a little fun.

📞 Click To Call Now

Reviews

There are no reviews yet